SF Cyclotouring

Ride reports and other ramblings from a San Francisco cyclist.

5/18/2015 - Day 6

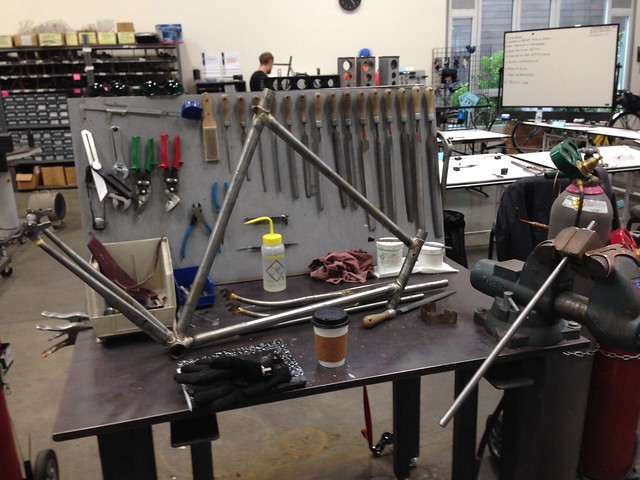

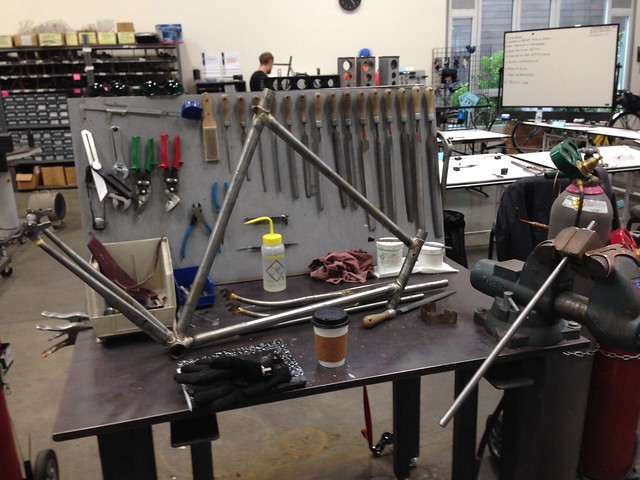

- After Brazing Main Triangle

- Examine the frame for any imperfections or needed touch-up -- mark these with Sharpie

- Inspect inside BB for silver penetration

- Too much silver needs to be removed by filing out with an appropriately-sized half-round file

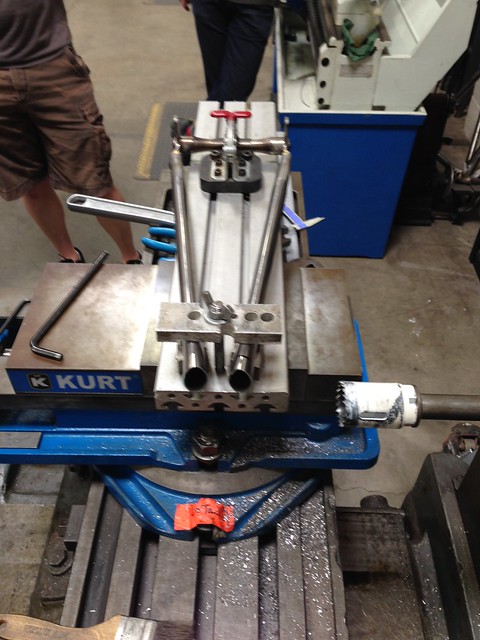

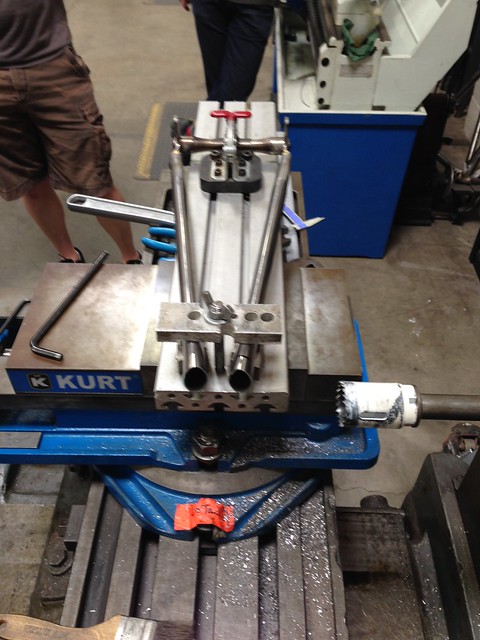

- Chainstay Mitering

- Rough-cut to ~15mm extra at BB end to allow for miter

- CAUTION: do NOT rough cut chain stays to the back-of-BB length!

- Get 132mm dummy axle, mount stays onto axle

- Put subassembly on drawing, mark CS tube length at back of BB shell

- Record the axle-to-back of BB measurement

- Set a caliper to the BB socket width

- CS Mitering done with 35mm hole saw, to match inside ID of BB shell

- Fillet-brazed bikes often have the chain stays offset lower to the BB to provide some clearance for the ST braze

- Lugged bikes have the chain stays lined up directly, not offset

- Miter on milling machine

- Chainstay Fitting

- Clean off burs from CS end

- Clean out BB ports with files and emery cloth

- Resize oval end of CS to fit BB port (squish in bench vise)

- Take length above BB (38mm) along seat tube ~500mm

- Triangulate on frame to determine CS angle/height

- Scribe line on edge of seat tube

- Check for free movement to desired position - file BB ports as needed

- Fillet-brazed frames need vent holes in chainstays & BB shell

- Chainstay Brazing

- Set up in jig

- Leave CS shy of inside BB port by 1mm to allow a ledge for silver filter to collect (otherwise it runs inside onto BB threads)

- Mark outside of chaintsays

- Set jig to correct BB drop

- Tighten center bolt of CS boom on jig first

- Check inside BB with flashlight to ensure proper CS position (leaving 1mm ledge)

- Check CS socket points on BB shell, use punches to tighten up ports as needed

- Brazing

- Flux inside and out, careful of the BB threads

- Flux halfway around the ST

- Paint extra flux up the chainstays (which will be pointing UP when brazing)

- Focus heat on BB since it's thickest

- Start on non-drive side

- Heat seam of port on BB

- Make sure BB stays hot since silver filler needs to flow there

- Frame Alignment

- Rear Dropouts

- Use Calipers to check OLD measurement

- Use H-tools for dropout alignment

- Use long length of flat stock placed under BB and under H-tool to check for even dropout height

- Use known-good wheel to check for rear triangle alignment

- Use frame alignment gauge (Park FAG-1 or similar)

- Check for even spacing at top of rim with long flat stock along main triangle

- Assess overall alignment picture

- Make a plan to correct alignment

- Bend chainstays to correct

0 Comments:

Post a Comment

<< Home