SF Cyclotouring

Ride reports and other ramblings from a San Francisco cyclist.

5/13/2015 - Day 3

- Third Lug Practice

- About Bike Frame Tubing

- 9/6/9 Butted wall thicknesses

- Butting lengths

- Can see butt transitions inside a clean tube

- Butted lengths vary widely, and can be asymmetric (one butted end is longer for trimming)

- Seat Tubes

- 28.6mm is most common, to fit a 27.2mm seat post

- Single butted for lugged construction

- Single-butted at bottom and EXTERNALLY butted at top for fillet-brazed construction

- Choosing Frame Tubing Diameters

- 1 inch steerer dictates 31.8mm head tube; be sure to choose an appropriate lug

- 8/5/8 tubing is light

- 9/6/9 is mid-range

- 1/7/1 is heavy

- Tubing choice factors

- Rider weight

- Rider strength

- Cargo load

- Frame size (larger frame implies stronger tubes)

- Pick lugs first, since these might limit your tubing options

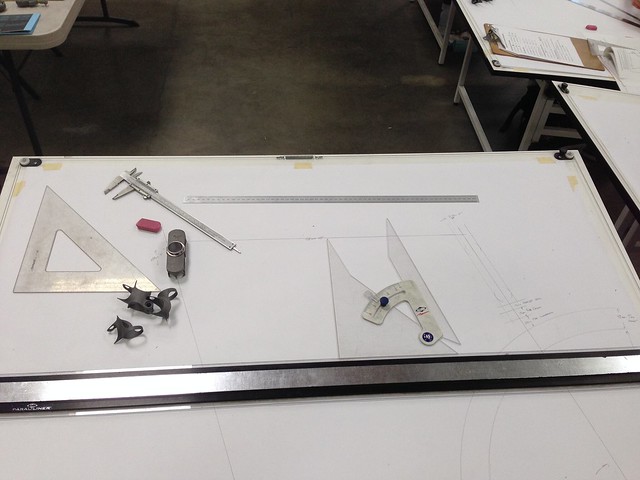

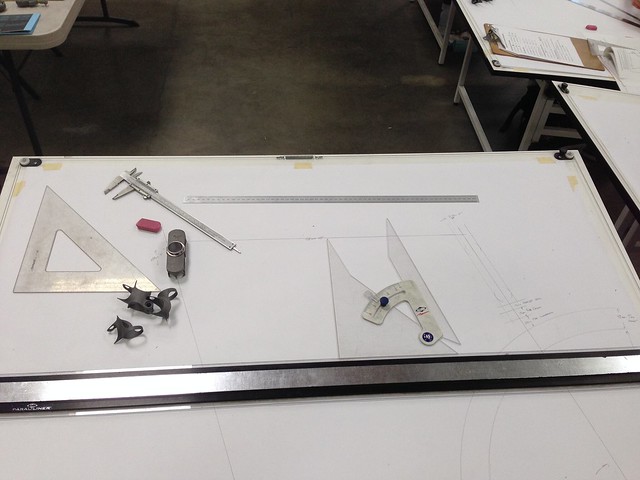

- Frame Drawing

- Work clockwise

- Use a SHARP pencil for accuracy

- Choosing the lower head lug is an iterative process due to unknown HT/DT angle

- Drawing steps (refer to workbook)

- Draw axle line about 7cm from bottom of paper

- Draw BB drop

- Draw seat tube centerline at correct angle from BB point and to desired length

- Draw TT centerline to desired length

- Draw HA/HT centerline back to axle line

- Draw Fork Offset parallel to HT centerline

- Draw arc set to radius appropriate to desired tire Bead Seat Diameter around front wheel axle center

- Choose a fork crown

- Consider caliper brake reach (if using caliper brakes)

- Draw in perpendicular line for 13mm lower HS stack height

- Measure lower head lug intercept

- Draw in headtube width (31.8mm)

- Add intercept distance

- BB shell

- For lugged, use the ID of the shell (typically 35mm)

- For fillet, use the OD of the shell (measure shell)

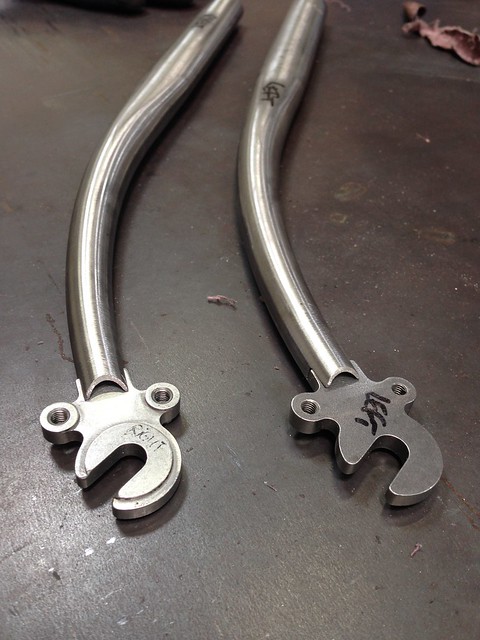

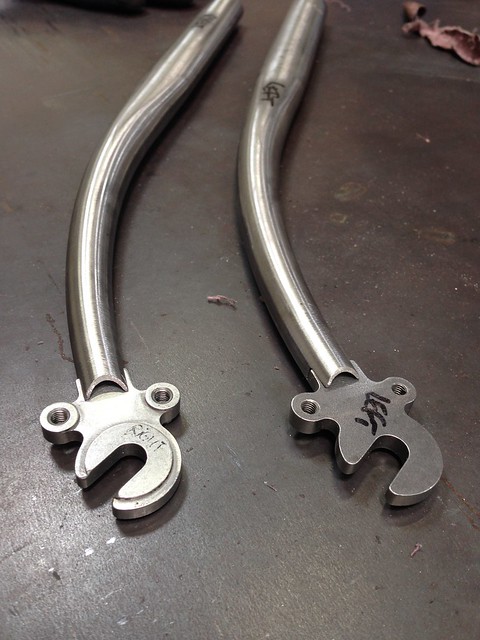

- Forks

- Dropout styles

- Tab style vs. socket style

- Socket style has more limitations for fork blades due to requirement for matching diameters

- Blade lengths

- Blade thickness

- Raking fork blades

- Check blade length before bending

- Iterate/sneak up on desired rake, alternating between both blades

- Get both blades as even as possible

- Cutting fork blade dropout slots

- 6-8mm depth is good rule

- Clamp using wooden blocks

- Sight down the bend/ridge of the blade to align the dropout slot

- Make a Sharpie mark

- Scribe width of dropout on blade parallel to sharpie mark, and centered with it

- Scribe slot depth onto blade

- Clamp and cut

- Bias the slots inboard for extra hub clearance

- Rotate the blade 90° and angle it to about 30° with floor

- Use a large flat file to knock down the corners and bevel the edge

- Use bevel protractor to gauge bevel against clamping blocks for repeatability with other fork blade

- Clean out burrs with round file

0 Comments:

Post a Comment

<< Home