UBI Framebuilding Class - Day 5

5/15/2015 - Day 5

- Frame Tubing

- Choosing Frame Tubes

- 8/5/8 is OK to use

- Wall thickness

- Overall length of tube should reach to at least halfway across adjacent tubes

- Check seat tube with actual seat post to ensure fit and determine butted/non-butted ends

- Locate tube butting (look inside)

- Watch for short vs. long butts

- Bias long tube butts towards the headtube

- Mark tubes just past center of adjacent tube

- Label tubes and their orientation

- Machining Dimensions (see worksheet)

- TT/ST: 73°/17°

- TT Miter Length: inside corner to inside corner

- TT/HT: 73°/17°

- Notch ST for Lugged BB, Notch DT for Fillet-brazed BB

- Tube Mitering

- On the Milling Machine

- Diameter of Cutting Tool/384 = approximate cutting RPM

- By Hand (specific to TT/HT Joint, others similar)

- Only rough-cut one end

- Scribe to inside of headlug

- Use Bevel Protractor/angle gauge set to HT/TT angle as filing guide

- Cut miter and file

- Clean out inside of tube (file/emery cloth)

- Scribe mark down length of HT for vent hole locations

- Drill 0.25-inch hole (#3 drill bit)

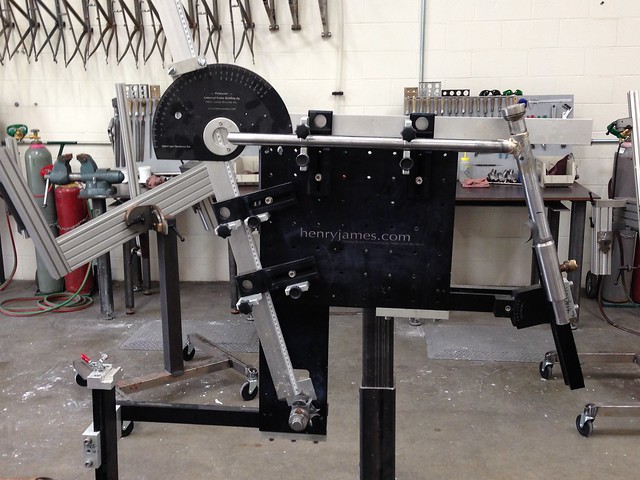

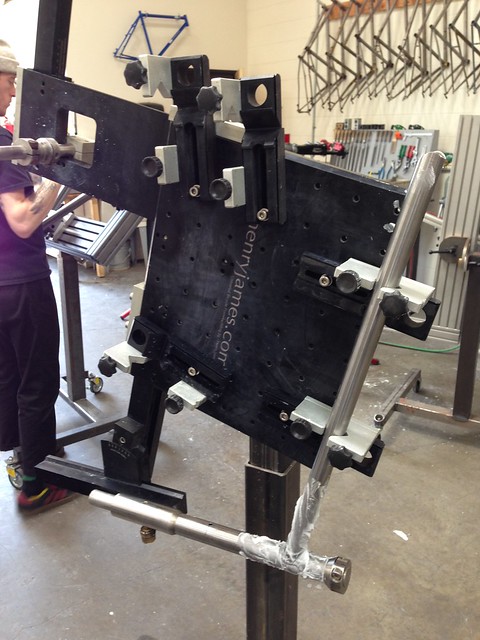

- Henry James Jig Set-up (specific to HT/TT)

- Level out the TT blocks against the jig's backplate with provided angle-iron

- Set centerlines for TT

- Adjust lower blocks first

- Adjust upper V-blocks next

- Set Head Angle -- watch for loose gauge block

- Head Tube Rod - put HT on

- Head Tube Height Adjustment

- Align HT vent hole with TT

- Check HT height from drawing

- Rock tubes in lug to ensure they're fully seated

- Make sure all clamp bolts are tight

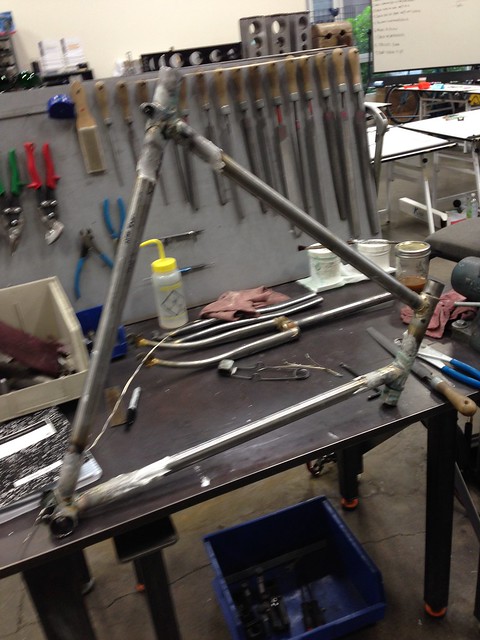

- HT/TT Brazing

- Silver flux everything

- Rotate jig to expose obtuse angle of tubing/lug joint

- Tack obtuse angle

- Tack acute angle

- Follow brazing sequence to complete lug braze

- "Paint" with torch flame to move the silver where you want it to go

- Seat Tube

- Notched for lugged frames to locate tube in BB

- Locate ST in BB and lay on drawing to locate ST/TT vent hole

- Check BB port angle against drawing

- Brazing the Frame

- Mount tubes in Henry James jig

- Ask instructor for help

- Flux everything

- Brazing

- Remember: Obtuse angles first

- Tip jig to point joint downwards to leverage gravity

- Use soft reducing flame, barely roaring

- Start w/HT/DT lug, braze similar to HT/TT lug

- Move to BB (rotate jig)

- Do obtuse/bottom/outside angle first

- Then do back/acute angle

- Don't cook CS ports

- FEed fillter at DT, look for it at ST

- Then do sides of ST

- Last do ST/TT lug, obtuse angle first (rotate jig)

- Feed filler at TT, look for it to come out at ST

0 Comments:

Post a Comment

<< Home